ASSESSMENT 03 THE DOCUMENTATION

Jiamin Li

z5108399

MODEL 01. HOUSE N

Video process

Finished Physical Model

Digital Model

Laser

cutting

Sanding white

acrylic by sandpaper (320 grit), the reflection disappear after sanding.

Material: White Acrylic 2 mm, Beech wood 2.5

mm, Natural Trees

Techniques: Laser cutting, sanding

Scale: 1:100

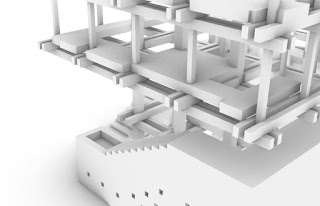

MODEL 02. NEST WE GROW

The model has been divided in to three parts, translucent facade, interior timber structure and timber base wall which can protect interior from the strong wind.

The most tricky part is the timber base. The original plan for making the base is CNC milling, while after discussing with CNC consultant, he suggested that using 3D printing will be a better solution in this case.

The reasons as following:

- The base wall is too small for CNC (the stair is 1.25 mm width while the smallest cutting in CNC is 6 mm);

- since all the internal angle should be straight angles, CNC internal angle only can with curve

- 3D printing has a cheaper price, around 10 -15 dollars can be done in this case.

Material: Frosted Acrylic, Timber,

Beech wood 2.5 mm

Techniques: Laser cutting and 3D printing

Scale: 1:100

MODEL 03. CRYSTAL HOUSE

Video process

Material: Clear Acrylic 2 mm, White Acrylic 2 mm,

Beech wood 2.5 mm

Techniques: Laser cutting, sanding

Scale: 1:100

评论

发表评论